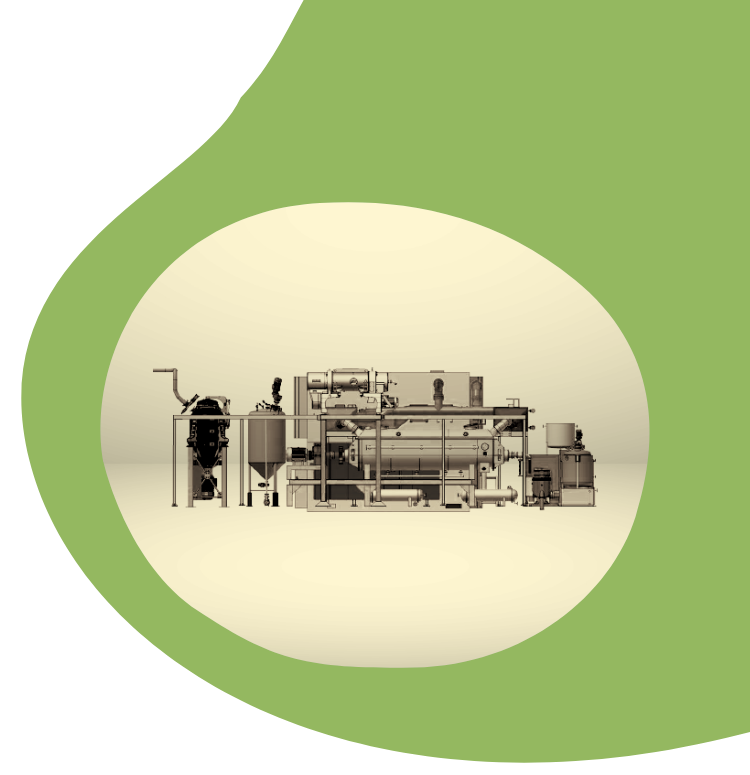

Celitron distributor

Trisun is proud to partner with Celitron in offering cutting-edge, sustainable, environmentally friendly solutions that transform animal waste and by-products into valuable ingredients for the animal feed industry.

Innovative solutions for the Agricultural & Medical sectors.